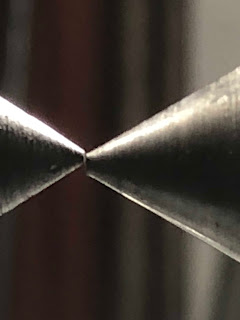

Started with a 0.2 inch strip of hot rolled steel. Marked out the shape and cut it on the HF band saw in the vertical position. The 2nd photo is the key after a bit of filing but not done.

To get the width just right the key was test fitted backwards in the tailstock keyway. Next it was tested in the final position. The lip that holds it in the tailstock had to come down quite a bit. The last image is the key installed with the quill in place. The stick out is there to aid in removal. Not sure if the original did but there is no harm in it.

The key is a tight friction fit in the tailstock and a sliding fit in the quill. The quill was tight but the key is fairly soft and it soon loosened up. Its a good fit with less play than the original key. It may help with the quill locking if it forces the quill to the top of the bore.