To align the tailstock we need to know the exact center of the headstock. This is done by turning a 60 degree taper which can later be used as a dead center. A pin with threads in the printers junk was used.

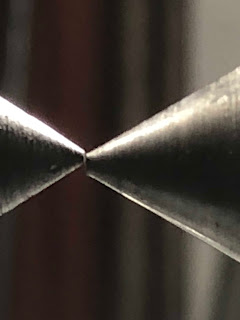

In these images you see a smooth center and a rougher one. The smooth is in the tailstock, other in the headstock.

The left image, with the dial showing, is taken from the top and illustrates the left/right alignment. This is easily adjusted with two bolts on the tailstock. Mr Pete shows a method using a dial indicator mounted in the chuck to check the center in the tailstock. The plan is to use this to further refine this alignment.

The right image is taken from the side and illustrates the up/down misalignment. Luckily the tailstock on the left is lower than the headstock and can be raised with shims between the two halves of the tailstock. The 'interesting' part of this will be getting the tailstock quill in line with the spindle. If its skewed it will make drilling difficult.

No comments:

Post a Comment