Finally found a procedure for honing kool bore blocks. By RED-85-Z51

myTractorForum

I've punched out a number of 11hp engines, among dozens more kool-bore engines.

I used a 2 stone rigid hone, and some ATF as lube...I ran the coarse stones on it until I could slip the oversized piston down the bore..(but not the rings). Then I swapped on the fine stones and started honing for...10 second intervals until I had set my ring gaps to spec, as checked at the top, middle, and bottom of the cylinder.

Ill reiterate, make sure a piston is available in the oversize you need, a bare piston will not work (aluminum piston on aluminum cylinder = instant gall). The piston will need to have the factory chrome coating on it.

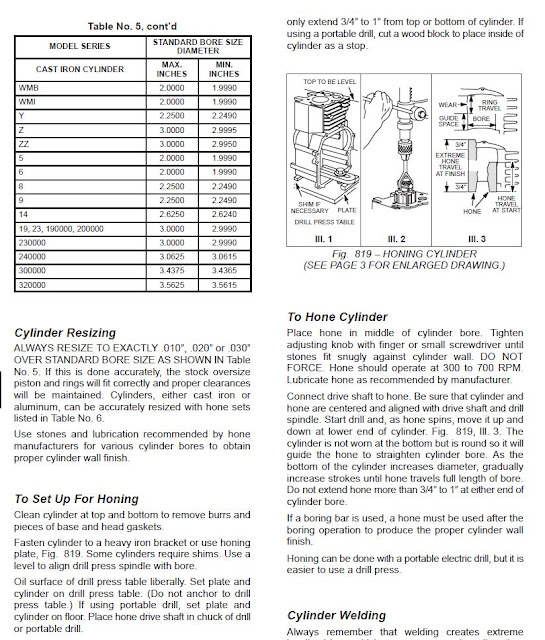

Also the briggs manual section 9 is the best boreing info I found so far.

Still been wondering about the grit used for Kool Bore cylinders. Briggs sells a hone set .

I ordered a set of 320 stones for the Lisle hone when I was researching this a while back.

No comments:

Post a Comment